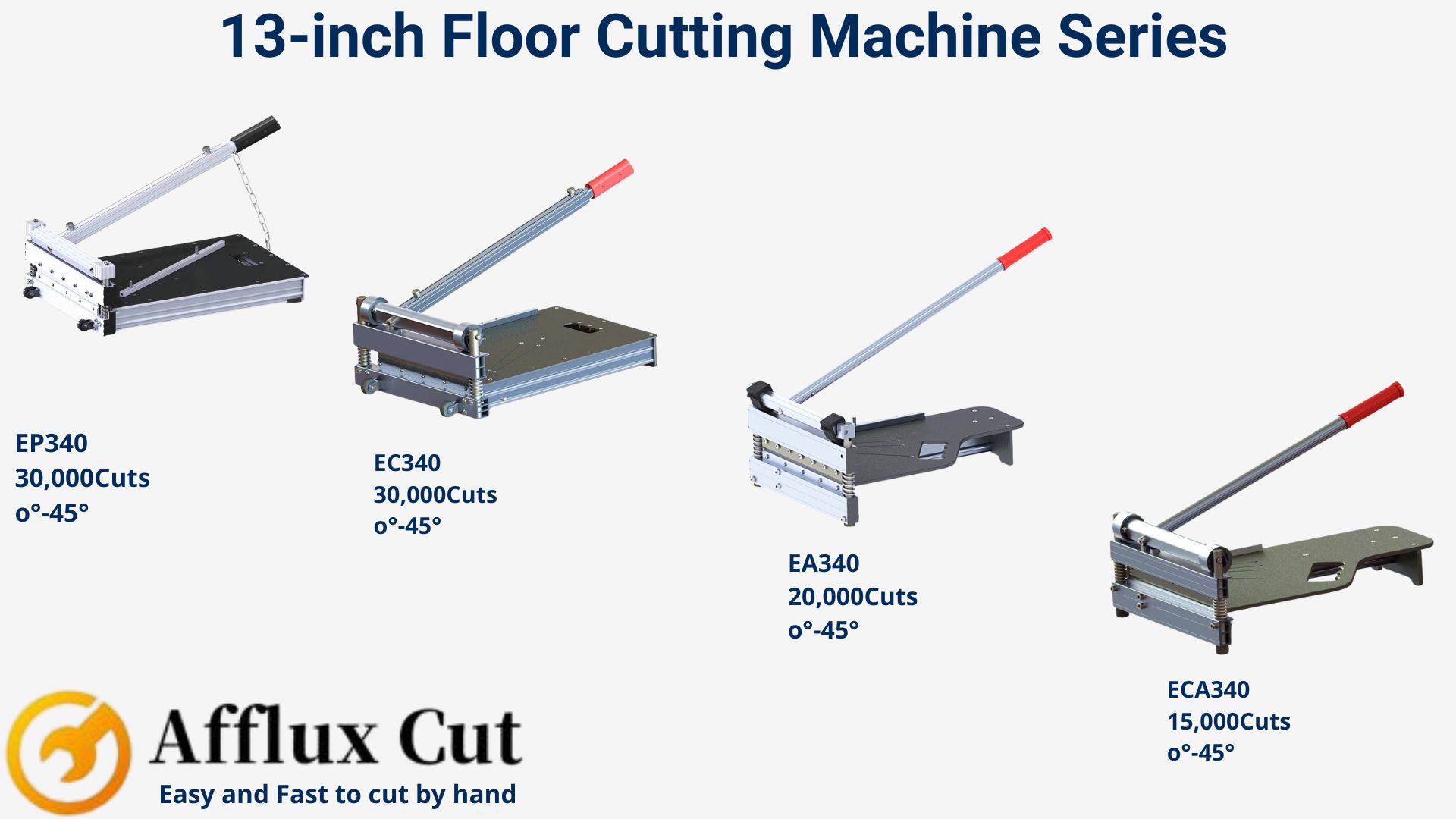

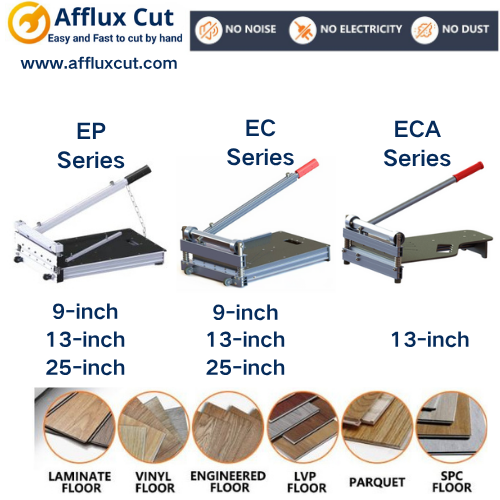

Inside the EC340: Why This Model Is Popular in the U.S. Market

1. Built for Professionals: Smooth Ergonomics Without Extra Effort

The EC340 was designed around a simple but powerful idea:

A cutter should be strong — but it shouldn’t be tiring.

Key Ergonomic Advantages

-

Extended leverage handle reduces required force when cutting thicker laminate or SPC.

-

Optimized pivot system creates a smoother push-down motion with less resistance.

-

Comfort-grip handle improves control during repetitive cuts.

These ergonomic upgrades help installers work longer, faster, and with less strain — a major reason U.S. contractors prefer EC-series cutters over basic, entry-level options.

2. 34 cm (13.4") Cutting Width: Perfect for Today’s Wide Plank Trend

The U.S. flooring market has shifted toward wider and thicker SPC / LVP planks.

The EC340 matches this trend with:

-

340 mm (13.4") cutting width

-

8–12 mm laminate and 4–7 mm SPC capability (depending on model variations)

This makes it compatible with the most commonly sold flooring products in Home Depot, Lowe’s, Menards, Floor & Decor, and specialty stores.

Distributors often comment that EC340:

“Covers 90% of the sizes our customers install. Easy to sell.”

3. Dust-Free Operation — A Strong Selling Point in Indoor Renovations

The U.S. market is increasingly sensitive to:

-

Dust control

-

Indoor air quality

-

Noise restrictions

-

Quick clean-up

Compared to a miter saw, the EC340 offers:

Why Contractors Prefer It Indoors

-

Zero airborne dust

-

Quiet cutting (won’t disturb customers)

-

No electricity needed

-

No messy cleanup

This feature alone makes it extremely marketable for:

-

Apartment renovations

-

Condo installations

-

Job sites where vacuum systems are inconvenient

-

Night-time renovations in commercial spaces

4. Durable Construction Designed for Rental Shops & Heavy Use

The EC340’s steel frame, reinforced base, and premium blade material allow it to survive:

-

High-frequency contractor use

-

Rental store cycles

-

Daily loading/unloading in work vans

-

Rough job-site conditions

Its durability is one of the key reasons distributors often reorder it:

“Fewer warranty issues, fewer returns, more profit.”

5. A Good Fit for OEM Branding (High Market Acceptance)

The EC340 has a strong track record with:

-

Tool brands

-

Flooring product brands

-

Retailer private labels

-

Amazon sellers

-

Regional distributors

What makes it OEM-friendly?

-

Flat surfaces for logo printing

-

Neutral, professional color scheme

-

Packaging that supports “premium positioning”

-

Balanced cost vs performance (high value-per-dollar)

For buyers needing their own brand, EC340 is one of our best-selling OEM bases.

Conclusion

The EC340’s success in the U.S. market is not accidental. It combines:

-

Better ergonomics

-

Practical cutting width

-

Job-site proven durability

-

Dust-free convenience

-

OEM adaptability

Whether you’re a distributor, tool retailer, or brand owner, the EC340 offers a reliable, professional-grade solution that aligns with current flooring market trends.

If you need detailed specifications, OEM options, or distributor pricing, our team can provide full support.

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Inside the EC340: Why This Model Is Popular in the U.S. Market

Inside the EC340: Why This Model Is Popular in the U.S. Market

How Retailers and Wholesalers Can Turn Flooring Cutters Into Profit Drivers

How Retailers and Wholesalers Can Turn Flooring Cutters Into Profit Drivers